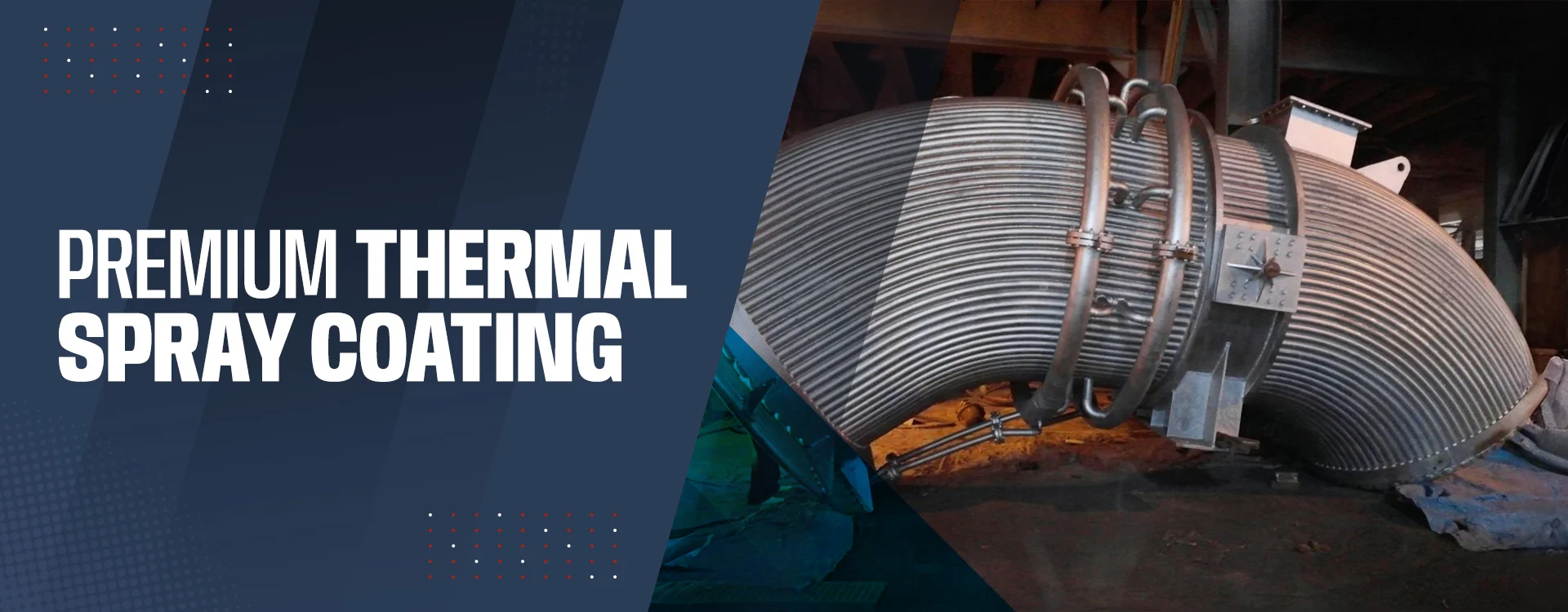

Thermal Spray Coating

Alloy Thermal Spray Pvt. Ltd. specializes in high-tech and premium surface protection together with the application of the latest technologies, such as HVOF, Twin Wire Arc, Flame Spray, TSA, TSZ, and Ceramic Coatings. We have a high-performance product line that includes solutions such as boiler tube coating, high-performance carbide coating, and coatings that are corrosion and wear-protective to critical industry parts in the Middle East, Africa, and India.

Redefining Durability Through Coatings

Alloy Thermal Spray Pvt. Ltd. has a team of experts in manufacturing high-quality thermal spray coatings with a capability to prolong the service life of industrial components, remove the inconvenience of any service interruption, and enhance maximum output. Supported with state-of-the-art infrastructure and a team of highly skilled professionals, we provide the service of HVOF, TSA, TSZ, Carbide, and high chrome alloy and coatings that suit the exacting requirements of industries in the power generation, oil and gas, marine, steel, cement, and petrochemicals. We have expertise in the development of coatings that can stand up to harsh environments and service for decades to prevent corrosion, abrasion, and high temperatures.

Comprehensive Thermal Spray Coating Solutions

We deal in a versatile list of thermal spray coating process technologies that provide protection to industrial parts against corrosion, wear, and high temperatures. We offer trusted solutions to power plants, oil & gas, petrochemicals, cement, marine, and heavy engineering sectors.

I. Protective Coatings – Our metallic coating is an aluminium, zinc, carbide, and alloy coating that is designed to protect the industrial parts against oxidation and erosion. These coatings not only enhance the strength of the equipment surface, but also greatly enhance the service life of the equipment, save on maintenance costs, and assure a consistent performance in the most extreme environments.

II. Thermal Spray Processes – Our highly-skilled team uses the latest technology in thermal spray, including HVOF, Twin Wire Arc, and Flame Spray systems, depending upon the specific needs of a part or industry. These processes provide maximum packed and consistent coating with extreme durability, which guarantees accuracy, efficiency, and consistency in the case of tough applications.

III. Specialized Applications – We go beyond normal protection and give specific coating to boiler tubes, turbines, pipelines, and heavy machines. Every application is also designed to counter the unique threats such as power, oil & gas, petrochemicals, cement, and marine, so that vital equipment stays productive, efficient, and safeguarded over a long lifecycle.

Solutions Tailored for Every Industry

| Category | Applications | Industries Served |

|---|---|---|

| Protective Coatings | Aluminium, Zinc, Carbide, and High Chrome Alloy coatings for corrosion & wear resistance | Power Plants, Marine, Petrochemicals, Oil & Gas, Steel, Cement, Heavy Engineering |

| Thermal Spray Processes | HVOF, Twin Wire Arc, Flame Wire, and Flame Powder Spray for durable and precise surface protection | Automotive, Aerospace, Steel, Chemical, Engineering, Manufacturing, Oil & Gas |

| Specialized Applications | Boiler Tube Coating, Turbine Protection, Pipeline Coatings, High-Temperature Resistance | Power Generation, Cement, Petrochemical, Oil & Gas, Marine, Pulp & Paper, Heavy Machinery |

Why Choose Us

Decades of coating expertise

Trusted across global industries

Advanced thermal spray technologies

Proven durability & performance

Tailored solutions for every need

Skilled & certified professionals

Strict quality & safety standards

Strong presence in India & abroad